Maintaining Excellent Standards for Industrial Sustainability

REMA TIP TOP commitment to sustainability

REMA TIP TOP is a globally operating system provider of services and products in the field of conveying and treatment technology as well as tire repair. For almost one hundred years, the company has built up unique expertise in materials development and industrial services and is active in the belting, material processing, surface protection and automotive sectors.

Global leader in industrial maintenance

As a global leader in industrial maintenance, REMA TIP TOP enables businesses in more than 170 countries to achieve their operational targets with a wide range of services, products and proven expertise. One of their vital goals is to advocate for industrial maintenance to prioritize repair and reuse over replacement to reduce material waste.

“Extending the life of industrial equipment is vital for both sustainability and efficiency,” says Michael Labbé, Executive Director at REMA TIP TOP. Sustainability does not just involve being kind to the environment but also being smart about resources and costs. This is where REMA TIP TOP’s maintenance experts come in and implement customer-specific strategies.

Sustainability is the responsible way forward

“We believe in sustainability because it’s the responsible path forward, both ethically and pragmatically. Our core mission is to provide outstanding solutions that genuinely benefit our customers. When we speak about sustainability, we’re talking about ensuring our customers’ long-term satisfaction, protecting the environment, and driving efficiency,” continues Michael Labbé.

Today, experts agree that predictive and monitoring strategies are more effective and sustainable than passive, corrective maintenance. Accordingly, maintenance is not a one-off project, but a continuous process that must be systematically managed. Consistency and discipline are the key factors in achieving excellent maintenance and operational results.

Repair and refurbishment over replacement of equipment

REMA TIP TOP’s maintenance services and solutions aim to support the circular economy. “Repair and refurbishment over replacement of equipment is our premise,” emphasizes Mario Delmaestro, General Manager Operations at REMA TIP TOP Middle East, who is a proven expert in comprehensive maintenance programs.

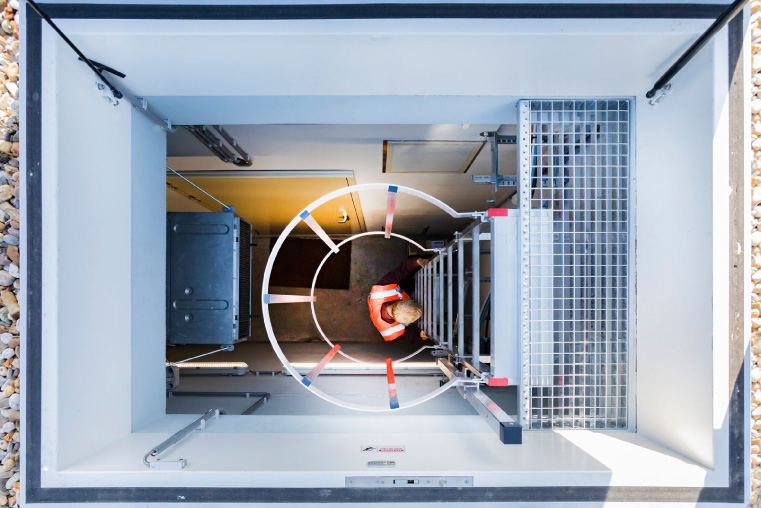

At REMA TIP TOP, a comprehensive maintenance plan begins with a detailed criticality plan, which serves as a guide for reliability-centered maintenance (RCM), preventive maintenance optimization (PMO), and failure mode and effect analysis (FMEA) plans. People are the most crucial component of any high-quality maintenance program, not only during the development phase but throughout the entire operational cycle.

Longer service life means less impact on the environment

By extending the lifespan of machinery and improving its efficiency, companies can lessen the strain on the environment, decreasing the need for new resources and minimizing waste. This approach enhances efficiency, reduces energy and resource consumption, benefiting both the environmental and the economic aspects.

To improve the operational reliability and sustainability of industrial plants, REMA TIP TOP offers its customers a full maintenance service, ranging from comprehensive inspections, repairs and modernizations, eco-friendly products and materials to tailored strategies to increase efficiency. Highest maintenance standards meet almost 100 years of experience.