How In2tec is turning ewaste into profit – and helping to save the planet

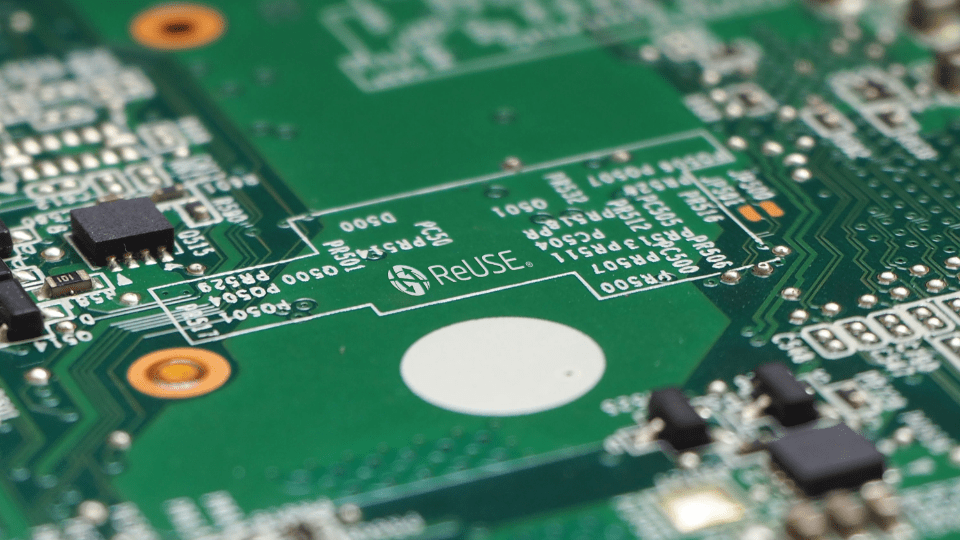

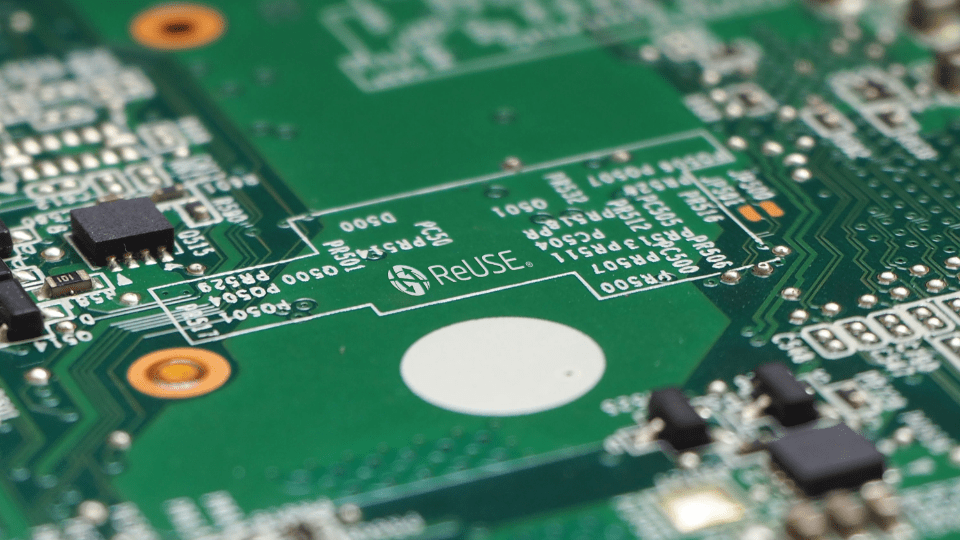

Sustainable electronics pioneer In2tec is proud to showcase its revolutionary ReUSE® and ReCYCLE™ technology, transforming the electronics industry and paving the way for a more environmentally responsible future in the sector.

For decades, the electronics industry has been reliant upon outdated materials and processes to manufacture printed circuit board assemblies (PCBAs). Current substrates and soldered components make electronics impossible to fully recycle, hazardous to burn, they never break down in landfill, and the manufacturing has a huge carbon footprint.

We generate over 62 million tonnes of ewaste globally each year, yet we document and collect just 22% of that due to the limited recycling opportunities, as the costs and effort significantly outweigh the gain. Ewaste is simply shredded into small pieces and most commonly smelting processes are used to extract base metals and precious metals, but these methods recover a fraction of the value that went into the electronics manufacture. All of the precious resources that went into making the components are destroyed despite having used a fraction of their available life.

This is a staggering waste considering these materials are running out and are vital to developing technological solutions to the problems humanity faces now and in the future.

Neil Armstrong, co-founder and Managing Director of In2tec, says: “The growth of digitalisation on the planet is significant. We’re consuming electronics at a rate of 6% more year on year.

“We’re producing one billion mobile phones a year and over 300 million laptops each year, we’re draining the natural resources of the earth and we’re not replenishing them. We can’t replenish them.

“We genuinely haven’t had the right solution. Until now.”

ReUSE® is a suite of patented inks, adhesives, materials, and processes and utilises proprietary design techniques to manufacture PCBAs, while ReCYCLE™ is the ultra-low energy process for unzipping PCBAs to the original bill of materials (BoM).

The state-of-the-art tech allows components and precious metals to be recovered without causing stress or damage, allowing for their reuse in next generation products or resale in the growing second-life market.

Neil adds: “The idea that a PCBA that can be unzipped, harvested, and reused at end-of-life turns around the current ewaste cost process of from a liability to an asset which changes the whole dynamic. The fact they now have a value means that we have a situation where people will want to recycle them”.

Ewaste causes devastating pollution to our water, soil, and air while raising the earth’s temperature to unstable levels. More than 90% of materials are either lost or remain unavailable for reuse. The Global Electronics Council reported that within the ewaste generated in 2021, over $68bn of valuable components were wasted.

Emma Armstrong, Sustainable Electronics Ambassador at In2tec Ltd, added: “We have 347 million metric tonnes of ewaste lying around on the floor somewhere on this planet, and that’s going to grow to 746 million tonnes by 2030 if we don’t do something about it.

“We first developed ReUSE® and ReCYCLE™ 15 years ago but the world was just not ready. Companies are generally not going to do things for the betterment of the planet without there being some financial gain for shareholders and stakeholders.

“That’s where our solution provides the answers – offering significant value for everybody from consumers through to manufacturers, recyclers, original OEM component manufacturers, and the people in developing countries mining these resources.”

Find out more about Economy 4.0 Campaign