Fuelling The Energy Transition with Renewable & Recycled Carbon DME

First Kind Of Waste-To-DME Plant For A Just Energy Transition

Dimeta is an independent joint venture between SHV Energy and UGI International, committed to accelerate the production and use of Renewable & Recycled Carbon Dimethyl Ether (DME) to decarbonise the off-grid sector.

KEW Technology is a sustainable energy solutions company efficiently converting waste and low-grade biomass, producing a portfolio of low-carbon gases, fuels and chemicals for application across hard-to-abate energy sectors.

The off-grid and waste challenge

The consequences of climate change are ubiquitous, magnifying the risks for instability in all forms. The global need to reduce greenhouse gas emissions and reach Net Zero by mid-century is more urgent than ever. Two of the critical pillars of minimising this is moving away from fossil fuels and tackling global waste pollution:

- Over one billion people live and work in remote areas not connected to the main gas grid. In these off-grid areas, gas and electricity networks are limited, leading to a heavy reliance on fossil fuels, such as oil or cleaner liquified petroleum gas (LPG), for heating, hot water, or cooking.

- Over 10% of global methane emissions pose environmental threats and challenge sustainable waste management practices.

Harnessing the potential of DME

Renewable liquid gases, like Renewable & Recycled Carbon DME, are a crucial aspect of the energy transition and a key to the solution. Renewable & Recycled Carbon DME is a sustainable liquid gas that can be produced through renewable feedstocks such as waste and is chemically similar to LPG. DME can be blended at 12% with LPG in existing infrastructure and appliances or used as 100% pure fuel in dedicated appliances.

Low-carbon DME can reduce greenhouse gas emissions by up to 85%, improve air quality and decarbonise the off-grid sector with no changes to LPG appliances or infrastructure. It can also achieve over 100% emissions savings when carbon capture is used. [/vc_column_text][vc_empty_space][vc_single_image image=”2771″ img_size=”634×350″ alignment=”center” css_animation=”fadeInUp”][vc_empty_space][vc_column_text css_animation=”fadeInUp”]

Circular solutions: Waste-to-DME

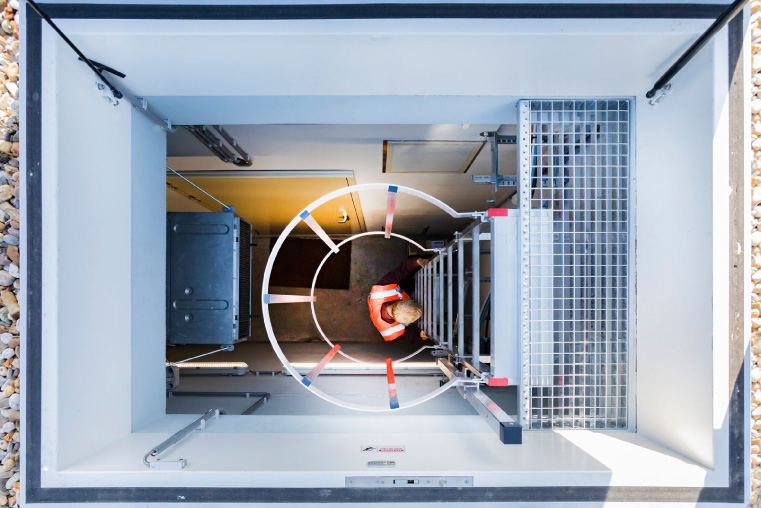

Dimeta is collaborating with KEW Technology to build a first of a kind waste-to-DME production plant through its partnership Circular Fuels Ltd. Located in Teesside, the UK, the facility will have the capacity to produce over 50,000 tonnes of DME per year – the equivalent of decarbonising 25% of the domestic LPG heating market. The facility is located on the UK’s largest Freeport and, in the future, could access carbon capture, utilisation & storage infrastructure, resulting in negative-carbon DME.

The waste-to-DME plant will take non-recyclable residual household, commercial and industrial waste and convert it into DME using KEW Technology’s proven advanced gasification process, a form of Advanced Conversion Technology. The sustainable fuel will then be used by the LPG Industry in a variety of applications, benefiting homes and businesses in rural areas not connected to the national gas grid. Moreover, this project will create job opportunities, with 250 roles during construction and over 50 permanent positions when production begins and will support indirect jobs in the feedstock and fuels supply chain.

Dimeta is the first company in the world to create waste-to-DME production plants by bringing together global industry leaders to shape a sustainable future.

Find out more about COP28 campaign