Unlocking the future of metal manufacturing

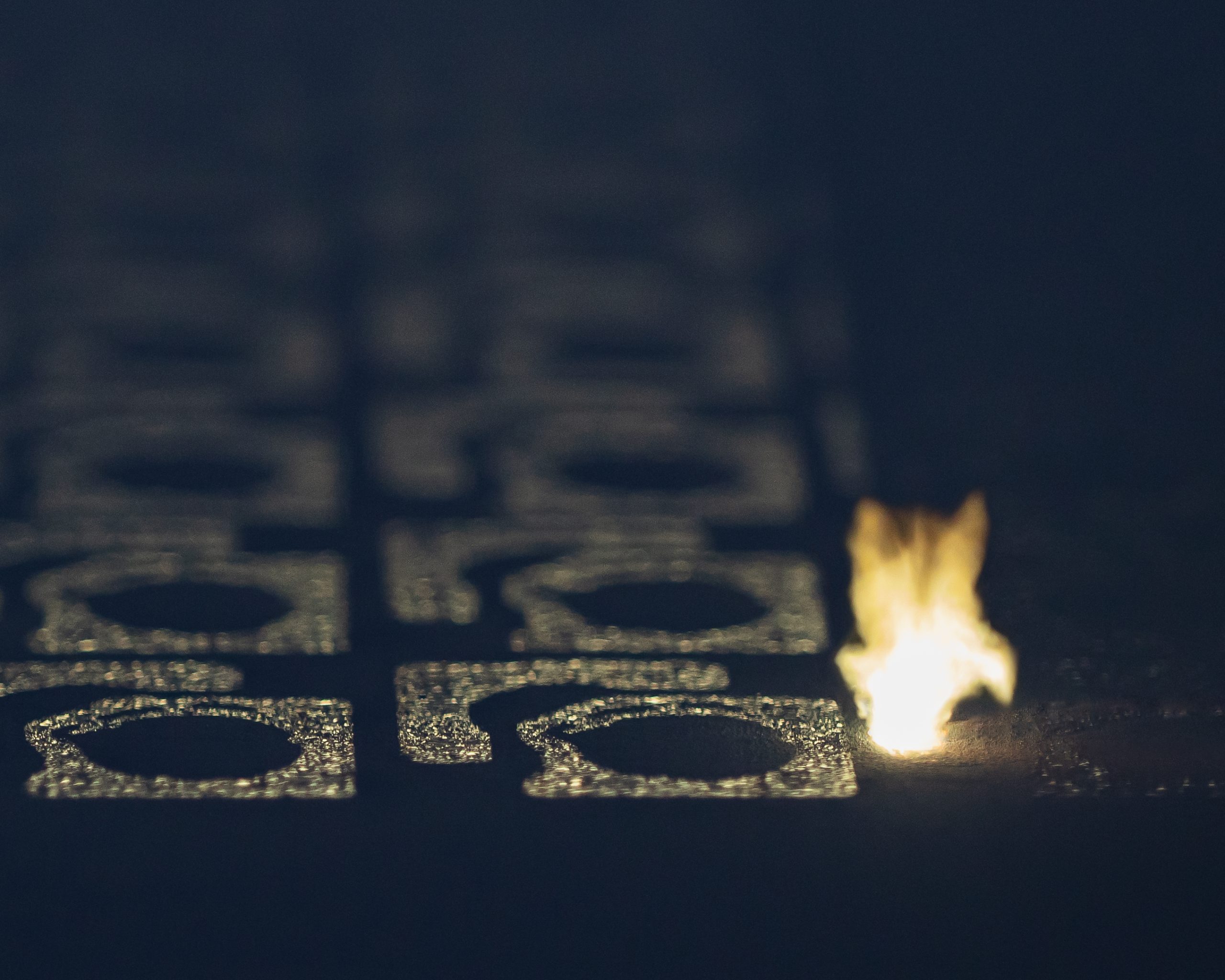

Creating the next generation of metal innovations and bringing them to market at scale is impossible with outdated manufacturing methods. Seurat is leading the charge by disrupting the metal parts production industry. Their future-ready manufacturing solution combines breakthrough Area Printing® technology with an innovative vertically integrated contract manufacturing model. Seurat is unlocking new possibilities for decarbonized, high-volume, high-quality metal part production that will help drive Economy 4.0.

Seurat partners with companies to transform their metal parts supply chains and product development workflows. With 100% clean-energy-powered print factories, Seurat delivers parts to customers faster, more efficiently, and with greater sustainability than ever before. For manufacturers, this accelerates innovation, enabling rapid design iterations and the creation of lightweight, complex next-generation products that would be impossible with the production constraints of traditional methods like machining, casting, or forging—or the limitations associated with conventional Additive Manufacturing (AM).

Seurat’s patented Area Printing technology lies at the heart of its manufacturing revolution. This fully digital, AI-driven process introduces a level of scalability that has eluded metal AM until now. It fundamentally shifts the cost dynamics of metal AM, transitioning it from a niche, low-volume process into a viable, cost-effective solution for high-volume production of the innovative parts businesses need.

Building these Area Printing machines wasn’t just a challenge—it was an opportunity to redefine the rules. By operating its own machines in its own print factories, Seurat can fine-tune performance, reduce production interruptions, and ensure every part meets unmatched standards for quality and precision.

Best of all, Seurat is removing traditional barriers to AM adoption. Manufacturers no longer need to invest in expensive printers, learn complex processes, or dedicate resources to maintaining machines. Instead, they can focus on what they do best: designing and innovating products. By partnering with Seurat, manufacturers get ready-to-use, high-quality parts delivered with speed and reliability. This eliminates the steep learning curve associated with in-house manufacturing and allows companies to accelerate their path to market.

Another advantage of Seurat’s approach is it brings high-paying manufacturing jobs back to local communities. The current economic landscape incentivizes not only the offshoring of manufacturing but also the relocation of skilled labor required to build today’s products. As a result, domestic industries face a decline in technical expertise and quality employment opportunities. While sourcing goods from the other side of the world may reduce initial costs, it introduces considerable risks -such as extended supply chains, geopolitical vulnerabilities, and decreased responsiveness to local market demands. Seurat addresses these challenges by reshoring manufacturing and regionally distributing its future print factories to align production with local needs. This localized approach will not only strengthen supply chains but also foster economic resilience and revitalize communities.

Seurat is more than a manufacturing partner—they are a catalyst for innovation. By unlocking the potential of additive manufacturing at scale, they are empowering manufacturers to dream bigger, innovate faster, and produce smarter.

Find out more about Economy 4.0 Campaign