Electrification Leads Way in Carbon Reduction

Axial flux motors, inverters and batteries are the components for electrifying everything that moves

The world will not convert to zero emissions overnight. However, several alternative power options make up the equation for decreasing carbon emissions now. These include:

- Biodiesel and other lower carbon biofuels

- Electrification

- Hydrogen (fuel cell and combustion engines)

At this moment, electrification leads the way because it is already widely used in passenger vehicles and smaller construction and agricultural equipment. In addition, the charging infrastructure is much more mature than biodiesel’s or hydrogen’s infrastructure.

What are some of the roadblocks to electrification of larger vehicles and equipment, and why do manufacturers need to electrify everything that moves?

Electrification Roadblocks

The charging infrastructure needs to be shored up, but it has improved during the last few years. Another challenge in the construction industry is that operators are resistant to move away from diesel because they fear electric equipment will not give them the power they need. However, this has been debunked by the electrification of medium-sized equipment (specifically the Volvo EC230 excavator).

Other roadblocks include the increased weight of electric components and space constraints under the hood. Battery modules and electric motors are historically larger than a diesel engine. And many manufacturers are attempting to put an electric system in the same space as the diesel engine. These under-the-hood challenges can be solved by selecting the ideal equipment.

Components for Electrification

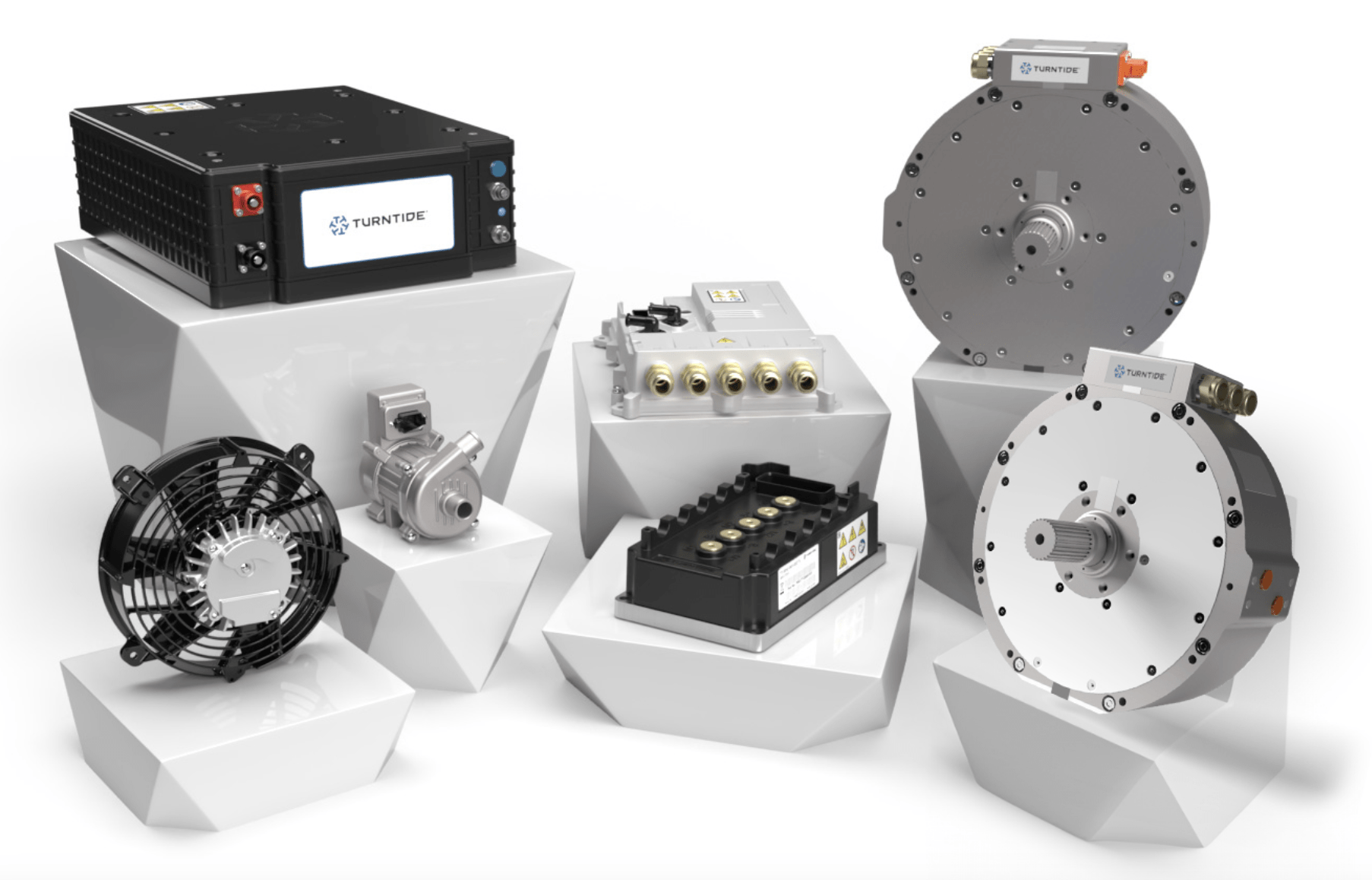

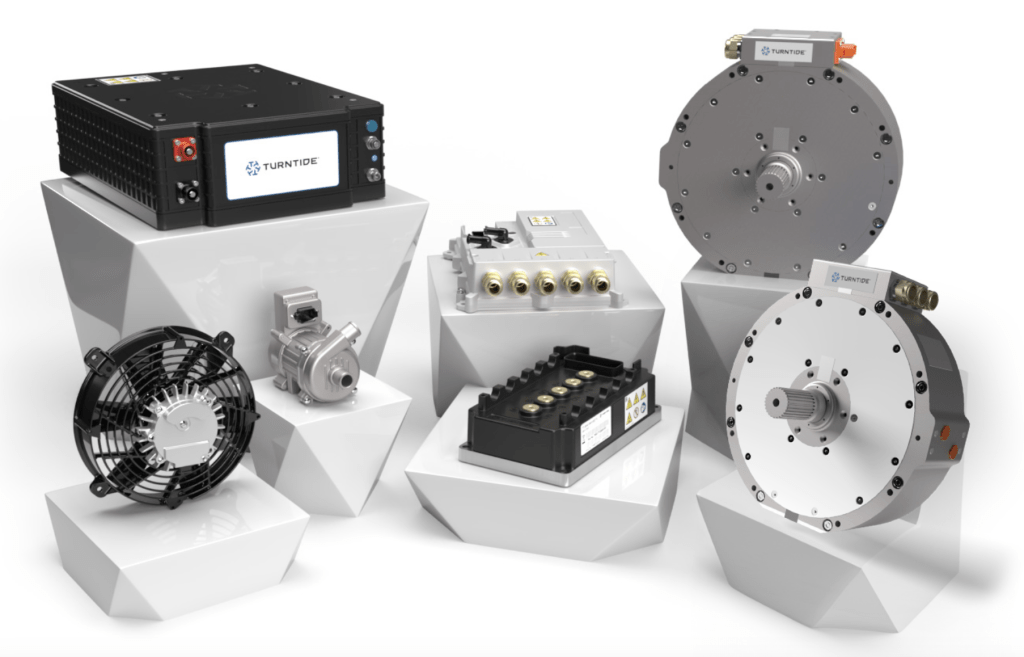

An electric system for a vehicle or piece of equipment needs electric motors (specifically, axial flux motors), power electronics (inverters and motor controllers), and energy storage (batteries).

Axial Flux Motors

Axial flux motors are flatter, often called pancake motors, than traditional electric motors. In space-constrained applications like hybrid and electric vehicles and equipment, these flatter motors are ideal.

Turntide’s axial flux motors can provide two to four times more power at 50% less weight. While the smaller size is important for axial flux motors to fit into electric or hybrid configurations, the decreased weight is also a major factor. In a vehicle, a 10% weight decrease means a vehicle range increase of 13% to 14%.

Inverters & Motor Controllers

A wide range of controllers and inverters is needed to cover the diverse vehicles and equipment. Turntide offers high-voltage inverters, low-voltage motor controllers, and direct-current (DC)/DC converters. They are solutions for many applications including traction, generation, and auxiliary functions, such as pump and fan applications.

Energy Storage

The Turntide new range of lithium-ion nickel, manganese, and cobalt battery solutions have an improved chemistry that provides a 15% increase in energy with improved gravimetric and volumetric densities. This new battery system combines high-performance battery packs with an external battery control unit that measures voltage and temperature parameters

The energy storage system allows customers a flexible and scalable approach to meet any energy storage solution. The battery is an ideal, rugged design for most off-highway applications ranging from construction and agriculture to marine and material handling.

Find out more about SDG Interviews

Axial flux motors, power electronics, battery electric, motor controllers, inverters, thermal solutions