3D-Printing Slashes Time-To-Power for Data Centers

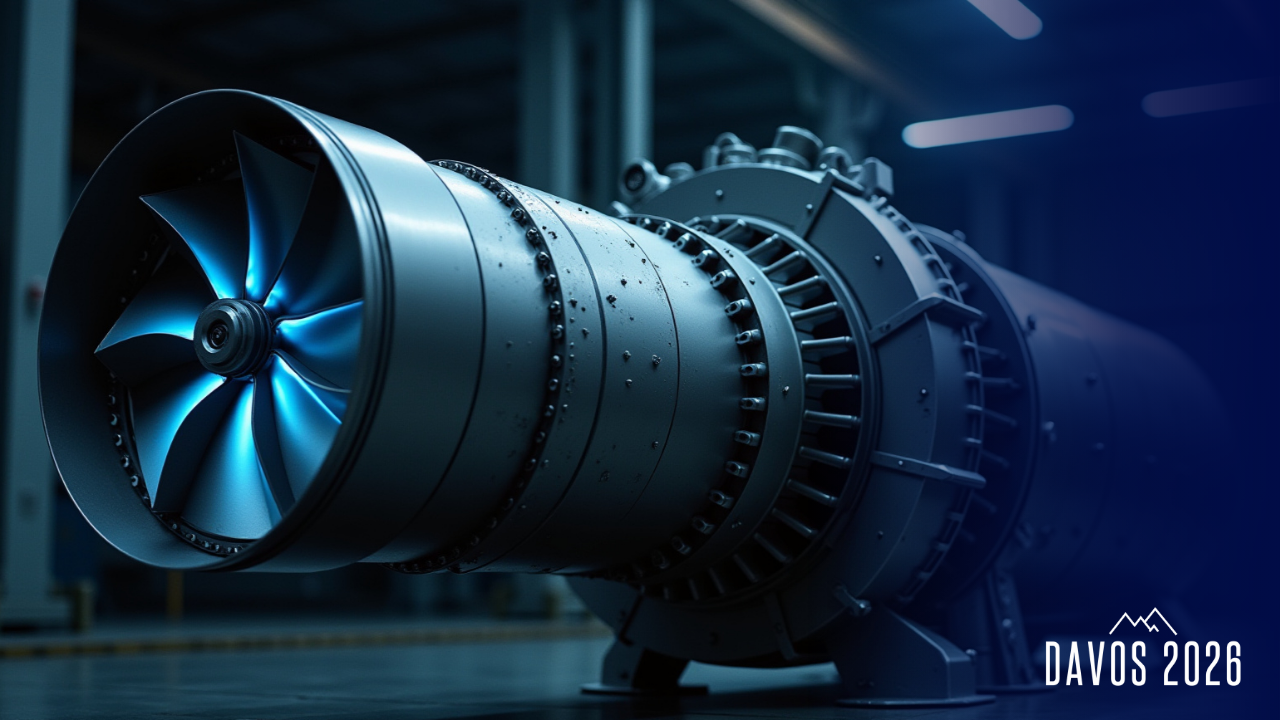

Additive manufacturing applied to purpose-built gas turbines solves the power problem for the AI data center infrastructure build-out.

Demand for electric power driven by AI data center build-out far outstrips supply

The projected demand for electricity to power new data centers driven by the growth in AI applications greatly outpaces current electricity grid capacities. Global data center capacity is projected to be up to 200GW by 2030 (source: Bain) and 80GW in the US alone, approximately 10% of the current US grid capacity. New data center projects are dealing with grid connection queues of up to 5 years, and traditional power generation equipment, like gas turbines, to build dedicated power plants for new construction is also sold out for 5 years.

Bottlenecks have become the main growth inhibitor for data center build-out and, by extension, for the forecasted economic growth projection enabled by AI. Large investments in AI chips and compute resources can only be amortized if the power infrastructure can grow accordingly.

A novel gas turbine entirely manufactured by additive technologies removes supply bottlenecks

Traditional gas turbines used for dedicated data center power plants utilize highly stressed large castings and forgings. These high-temperature alloy components are sourced via just a handful of suppliers globally, thereby reducing capacity and increasing lead times.

Novra Power has developed a modular turbine that leverages the capabilities of advanced 3D metal printing additive manufacturing technologies. Lead times for additive manufacturing parts are days rather than months, and capacity scaling is only restricted by investment not process timelines. This provides the unique opportunity to overcome traditional and currently exacerbated supply chain restrictions and provide a power generation technology that can keep pace with the build-out of the AI data center infrastructure.

Additive manufacturing enables unique design and performance advantages. Novra Power applies design to minimize part count, maximize material utilization and incorporate advanced cooling that leads to higher reliability and redundancy as well as lower maintenance. It also provides low emissions and highest efficiency.

Growth of western economies depends on rapid energy system build-out to enable AI driven growth

The growth of western economies depends on their ability to rapidly scale energy systems to keep pace with the demand of compute power to enable the projected AI-driven growth forecast. The current power infrastructure in most countries is limited by an aging and inflexible power grid that cannot accommodate the large nodes of power that new AI data centers demand. Data center developers divert to off-grid solutions utilizing gas turbines and other technologies like future small nuclear reactors.

In addition, the power generation equipment industry supplying these solutions is sold out for multiple years. With a dependency on a limited number of highly specialist suppliers, these bottlenecks are not going to be solved over the next decade.Novra Power (Novra Power | DataCenter Power Additive Manufacturing) has a patented approach for a 3D-printed gas turbine-based power solution that solves the supply chain bottlenecks and can be quickly scaled.

Find out more about DAVOS 2026 Campaign